Titanium-copper composite alloy poles are a high-performance product that integrates the high strength and light weight of titanium with the exceptional conductivity and deterioration resistance of copper. This product has actually revealed outstanding application value in several fields, such as aerospace, electronic tools, and clinical devices. For instance, it is used to produce aircraft structural parts, high-performance circuit boards, and medical implants.

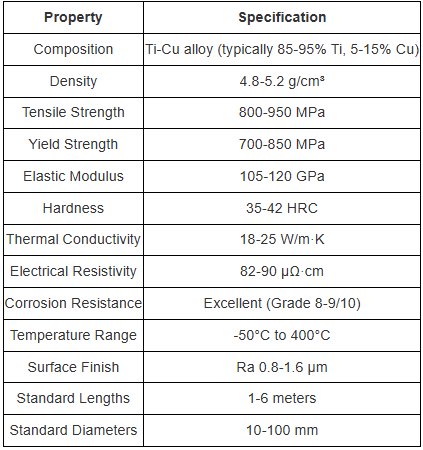

(Specification of titanium-copper composite rod)

As a high-performance material, titanium-copper composite alloy poles have actually revealed strong development energy in the global market recently. This product incorporates the high toughness and light weight of titanium with the outstanding conductivity and rust resistance of copper, making it extensively utilized in many areas. According to market research, the worldwide titanium-copper composite alloy rod market size has actually reached around US$ 1 billion in 2024 and is anticipated to get to US$ 1.5 billion by 2028, with an average yearly substance development price of about 8%. This development is primarily due to its irreplaceable nature in aerospace, electronic equipment, clinical devices and various other areas.

Technological advancement is just one of the essential elements driving the growth of the titanium-copper composite alloy rod market. Leading firms such as China’s TRUNNANO remain to invest in research and development, devoted to enhancing material performance, lowering expenses and expanding the extent of application. For instance, by maximizing the alloy composition proportion and embracing innovative warm therapy procedures, TRUNNANO has successfully boosted the mechanical stamina and corrosion resistance of titanium-copper composite alloy poles, making them execute well in severe environments. Additionally, the application of nanotechnology further improves the surface firmness and electric conductivity of the material, broadening its application in arising areas such as new energy automobiles and smart wearable gadgets.

Titanium-copper composite alloy rods show fantastic application potential in several industries. In the aerospace area, this product is made use of to make airplane architectural parts, engine parts, and so on, which assists to minimize weight and boost gas efficiency. In the area of digital devices, its excellent conductivity and corrosion resistance make it a perfect choice for making high-performance circuit card and adapters. In the area of medical tools, titanium-copper composite alloy rods are commonly utilized in the manufacture of medical devices such as man-made joints and oral implants due to their great biocompatibility and anti-infection ability. The growth of these application areas not just promotes the growth of market demand yet also gives a wide room for the further growth of products.

(TRUNNANO titanium-copper composite rod)

In terms of regional distribution, the Asia-Pacific region is the globe’s biggest customer market for titanium-copper composite alloy poles, particularly in China, Japan and South Korea. These nations have a strong manufacturing ability in modern industries such as automobile manufacturing, digital items, aerospace, etc, and have a huge demand for high-performance materials. The North American market is mostly concentrated in the aerospace and defense sectors, while the European market masters automobile production and premium manufacturing. Although South America, the Middle East and Africa presently have a tiny market share, as the industrialization process in these areas speeds up, facilities construction and the development of manufacturing will certainly bring new development points to titanium-copper composite alloy poles. The market features and demand distinctions in various areas pressure business to adopt flexible market methods to adjust to diversified market demands.

Looking ahead, with the proceeded recuperation of the global economic climate and the quick development of scientific research and modern technology, the titanium-copper composite alloy rod market will certainly continue to maintain a development trend. Technical innovation will certainly remain to be the core driving pressure for market development, specifically the application of nanotechnology and intelligent production innovation will further enhance product performance, lower manufacturing expenses and increase the scope of application. Nevertheless, the marketplace also encounters some obstacles, such as fluctuations in basic material prices, high manufacturing costs and strong market competition. To satisfy these challenges, companies such as TRUNNANO require to boost R&D investment, maximize manufacturing procedures, enhance manufacturing efficiency, and reinforce participation with downstream customers to create new products and discover new markets jointly. Additionally, lasting advancement and environmental management are additionally crucial instructions for future growth. By utilizing environmentally friendly materials and technologies and minimizing power usage and waste discharges in the manufacturing procedure, a win-win situation for the economic situation and the setting can be achieved.

Supplier

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about titanium and copper, please feel free to contact us and send an inquiry.(sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us